FORGING

YOUR IDEAS

INTO

INNOVATIVE

SOLUTIONS

INNOVATION

Becoming a market leader in our sector requires constant investments in R&D to ensure cutting-edge production facilities and exclusive know-how.

In support of our clients’ competitiveness, we offer our full technical assistance, which manifests in advanced resources and technologies used by a dedicated team charged with the development of projects aimed at improving the cost-quality ratio of the products.

Thanks to process engineering and the guidelines developed over many years of experience, Brawo studies and plans the most suitable production cycle for the realization of each product.

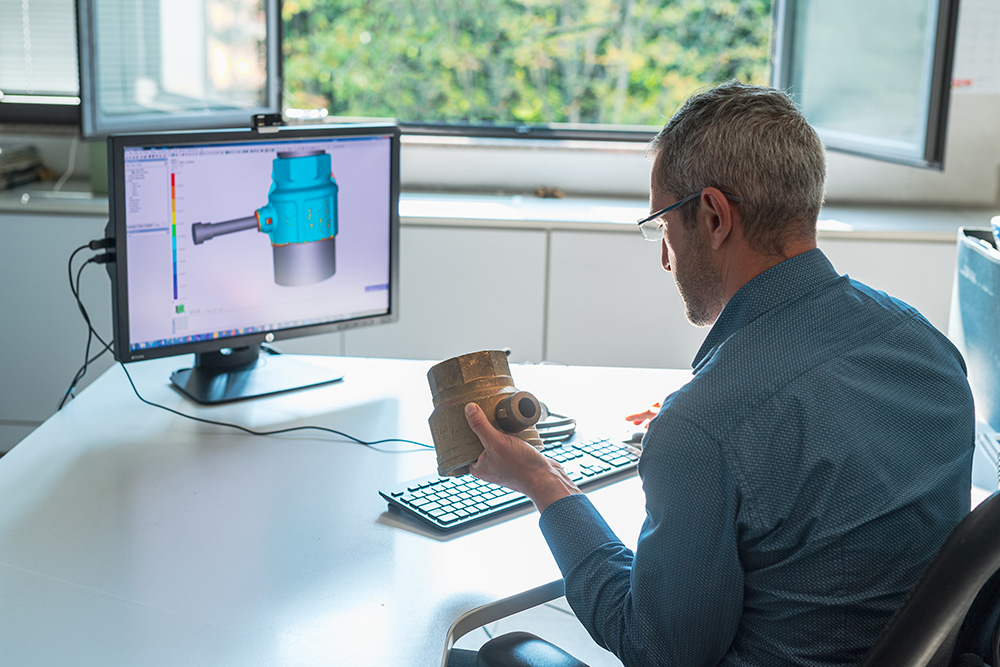

Innovative forging simulation software is used to prepare our Customer’s parts for production.

The forging simulation catches any possible cause of process failure before we ever have to forge a part.

Forging simulation allows us to achieve more efficient results, eliminate the risk of error on the finished product, and significantly reduce time-to-market.

During the planning phase of the machining process, Brawo also carries out FEM – Finite Element Method – analysis, to prevent any negative effects caused by deformations due to the parts positioning and clamping systems.

Another software we use is MES – Manufacturing Execution System. With this tool, Brawo monitors and manages every aspect of production. In particular, the software allows us to verify-in real time- the productivity of machines, the traceability of parts and tools, and the organization of maintenance and quality services.

Efficient and adaptable solutions are crucial to achieve more flexible production and higher productivity levels.

Efficient and adaptable solutions are crucial to achieve more flexible production and higher productivity levels.

The 4.0 technology model used by Brawo is the interface between machines and our Manufacturing Execution Software.

Among the various innovation projects that Brawo is developing, our digital work instructions allow operators to have all the information that previously had to be collected in different departments, available in a single digital document close to the machine. Therefore, each operator has all the information required for production at the click of a button.