FORGING

YOUR IDEAS

INTO

INNOVATIVE

SOLUTIONS

QUALITY

Quality is at the forefront of everything we do. For Brawo, quality is embodied in sharing our customer’s objectives and in our commitment to achieve them every day.

Since 2015, Brawo has implemented and obtained the certification of our Automotive Quality Management System in compliance with IATF 16949.

At BRAWO we have established an effective product and process monitoring system to ensure customer requirements are met:

- Thanks to our highly trained and skilled staff.

- Our engineering team develops robust control plans after evaluating the strengths and weaknesses of the production process.

- We verify our customer’s requirements with respect to drawings, standards, technical specifications, contractual clauses, expected requirements for applicable laws and regulations.

- Regular inspections are performed and monitored throughout the entire production cycle by our trained staff.

- BRAWO’s customers’ high quality expectations are met and exceeded with the assistance of our state-of-the-art monitoring and measuring equipment.

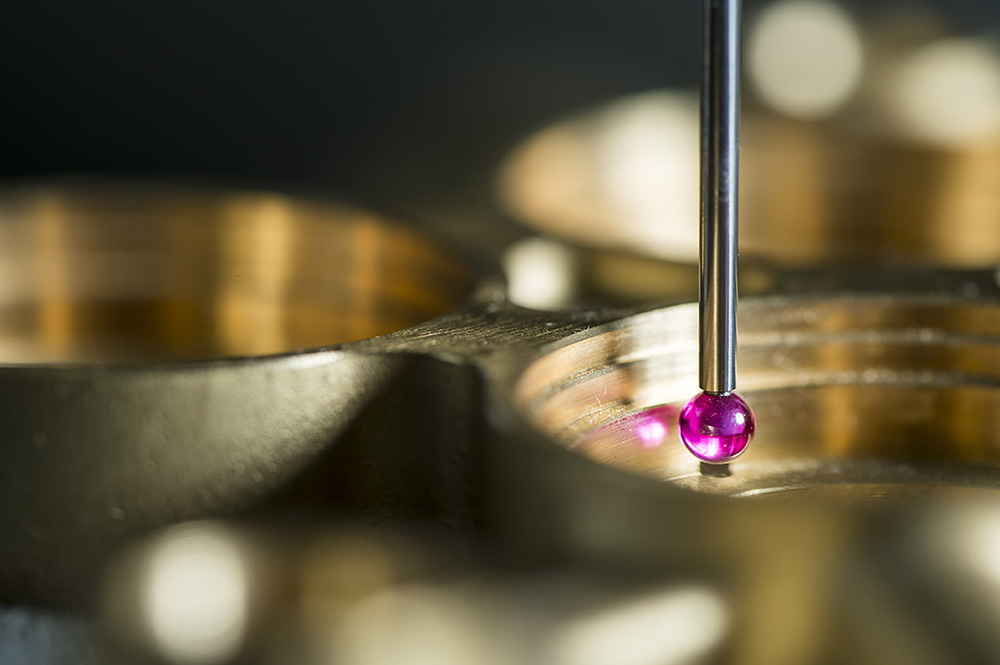

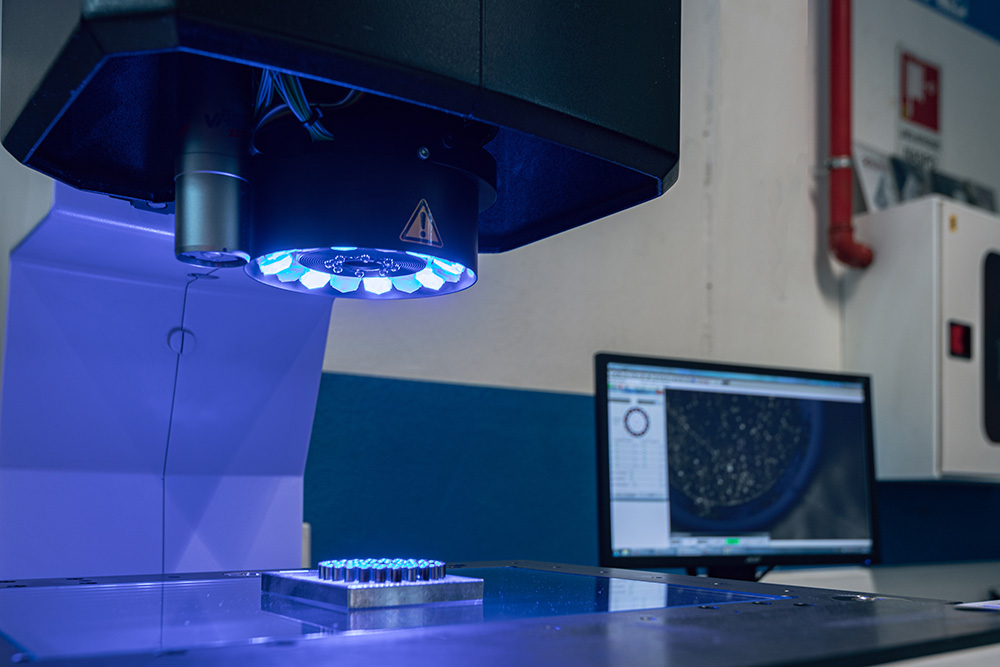

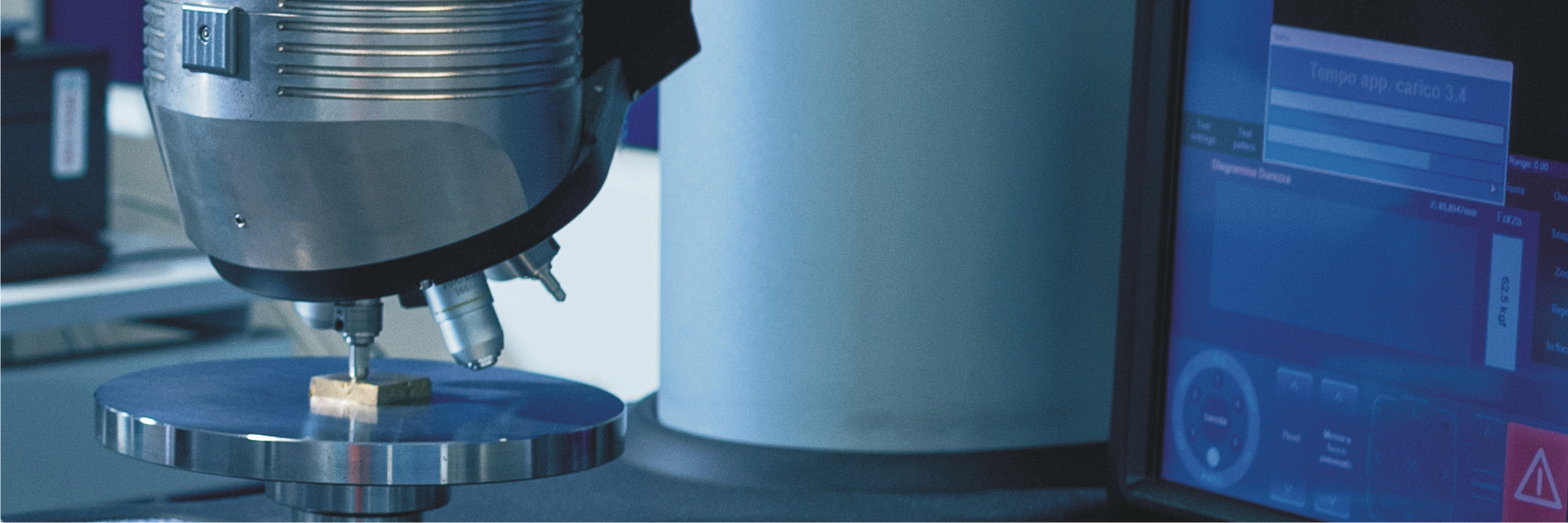

Brawo has a state-of-the-art metrology laboratory equipped with four Zeiss three-dimensional machines that are inclinable and able to measure in all directions, and a fifth multi-sensor three-dimensional machine that allows for optimal measurement of any feature, optically or by contact. There are also several Duramax Zeiss three-dimensional CMM machines positioned along the production lines.

The tools at our disposal, such as profilometers, roughness testers, high-speed 2D optical micrometers and profile projectors are the best in the industry. All measuring and monitoring equipment is regularly calibrated by accredited laboratories.

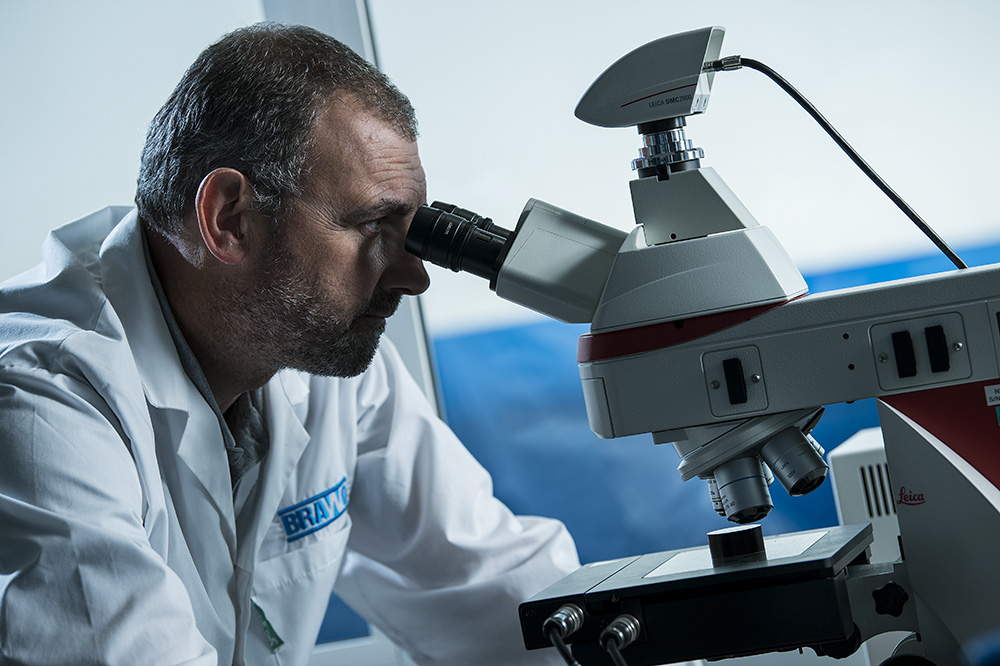

Our metallurgical laboratory was created to optimize aluminum forging by verifying material features throughout the production process.

Through destructive, corrosion resistance, and hardness tests; constant monitoring, micro and macro analysis and dezincification, the metallurgical laboratory is able to define compliance with specific requirements, to perform studies aimed at continuous improvement, and to support any customers’ requirements. Various microscopes, spectrometers and durometers, regularly checked and calibrated, are just some of our the latest-generation equipment. Upon test completion, our lab produces a report confirming that quality requirements have been met. Brawo works with external accredited labs to run any further tests or analysis required by customers.